Supply chain & traceability

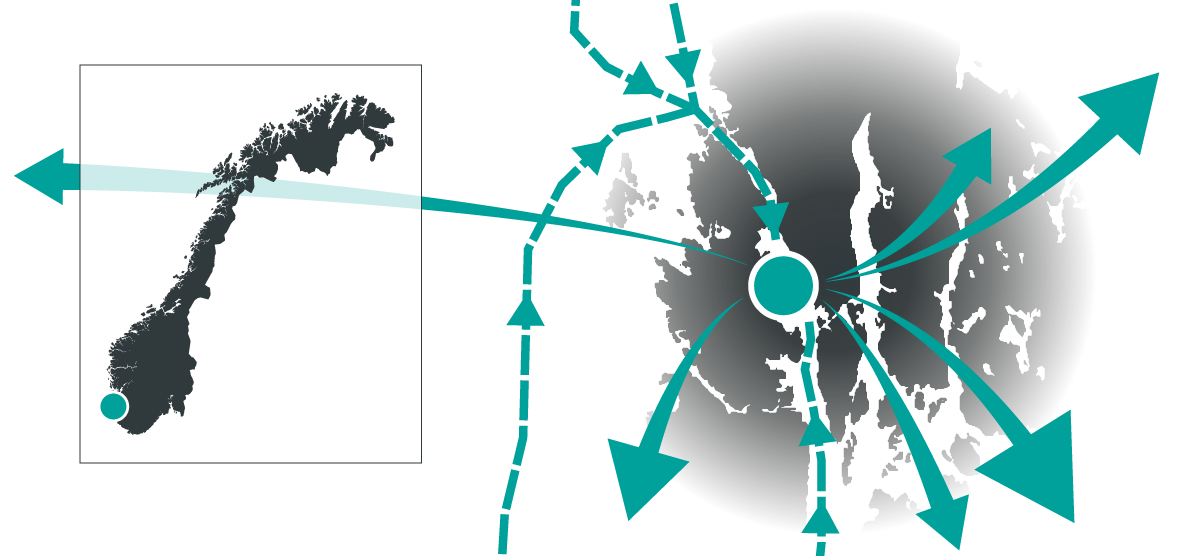

Alginor seeks to raise the bar for traceability in the kelp ingredient industry. To that end, we are developing a transparent, traceable and vertically integrated value chain, enabling us to document the products’ entire life cycle — from harvesting of Laminaria hyperborea in the cold Norwegian waters to finished ingredients distributed to the global markets.

Like our customers, we place a high value on complete traceability. In order to achieve this, we believe it is essential to oversee and control each link of the value chain. We value this particularly high because it allows us to track and document every detail and input of our ingredients’ journey and provide our clients and our clients’ end-users with full transparency and reliable traceability — from start to end. This is important not only as a unique selling point among manufacturers and consumers with an increased focus on origin and life cycle, but also because vertical integration is a means for ensuring ingredient safety and performance in pharmaceutical and nutraceutical products where our products are used as ingredients.

To ensure product quality and safety throughout the supply chain, it is necessary to stabilise the biomass rather quickly after harvesting to prevent oxidised degradation and development of unwanted bacterial floras. Millions of animals and microorganisms are also present in the kelp’s epiphytes and holdfast and need to be removed at some stage of the supply chain. Solving these issues is important both from a safety perspective and to prevent unwanted brown discolouration caused by polyphenols.

Our approach to solving these issues and what sets us apart from our competitors, is that we do not use any formaldehyde or other toxic preservatives to stabilise the biomass. Instead, we control these factors by strategically separating the raw material into distinct fractions. Through this process, we create intermediate kelp ingredients that are more storage stable without any added preservatives.

Our goal is to provide a sustainable and diversified portfolio

of traceable, pure and high-quality ingredients

to the global markets.

The process of raw material separation facilitates for highly optimised downstream processing and high-quality production outputs. As a result, we achieve excellent traceability throughout the supply chain by being able to trace each ingredient back to the specific fraction of the kelp. Identical to our upstream processes, green chemistry and mild processing conditions are cornerstones in our downstream processes and does not involve formaldehyde or any aggressive substitute process chemicals.

Our supply chain is designed to avoid as many direct and indirect contaminants as possible, providing an extra layer of traceability. In terms of sustainability and sustainable production, we aim to fully utilise any biomass we bring to shore through biorefining — wasting nothing downstream. Our goal is to provide a sustainable and diversified portfolio of pure, high-quality ingredients to global markets. To this end, we believe that our methods combined with complete supply chain control are imperative.